How Do Bearings Support Clean Wind Energy?

Wind turbines are revolutionizing the energy industry, shifting consumers away from fossil fuels, nuclear power, and other non-renewable energy sources towards an environmentally friendly and sustainable future.

Such an undertaking has its challenges, however, and these massive machines must operate in demanding and constantly changing conditions, whether on or offshore.

Severe weather, varied loads, remote locations, and restricted maintenance accessibility contribute to the extreme environment of these highly engineered pieces of machinery.

So, to generate power effectively and meet their full 25-year service life, wind turbines require the highest quality and performance from all of their components.

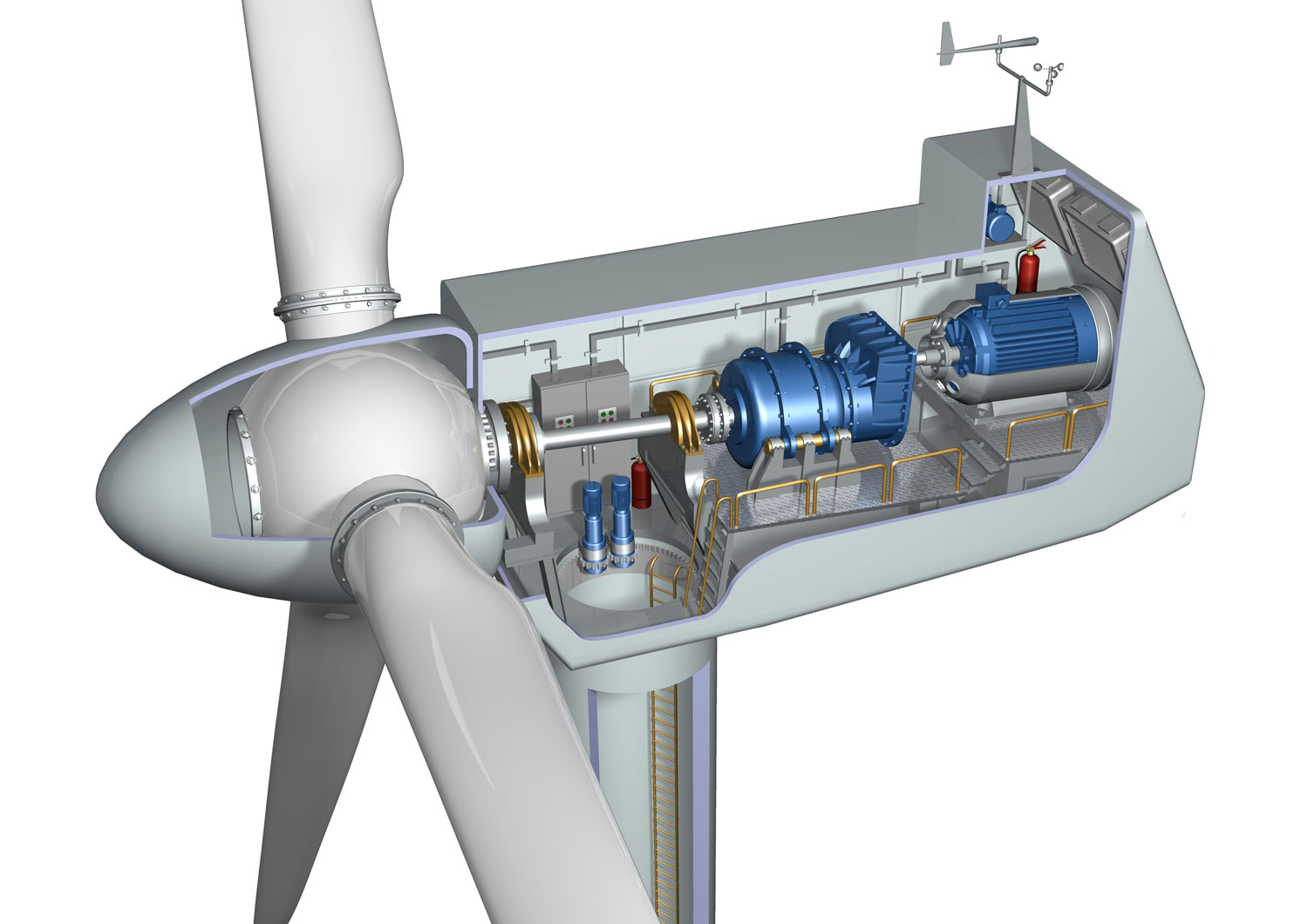

Some of the most important elements within a wind turbine's drivetrain are the bearings, particularly in the main shaft and gearbox, which are essential components in the turbine's operation. The gearbox connects the low-speed rotation of the rotor blades/hub's shaft to the high-speed rotation of the generator's shaft.

The transition from low to high speed inside the gearbox allows the generator to produce electricity. In the main shaft, large roller bearings support and withstand heavy axial and radial loads. Meanwhile, bearings in the gearbox must absorb high transient loads and facilitate slow to fast operating speeds.

Bearings in The Main Shaft

The main shaft in a wind turbine's drivetrain connects the rotor on one side to the gearbox on the other. It rotates at relatively slow speeds (around 10 rpm) but must tolerate axial and radial loads alongside harsh, persistently variable loads and conditions.

The bearings used within are also subjected to high and dynamic axial and radial loads and exposure to corrosive seawater in offshore applications.

Spherical Roller Bearings are used along the main shaft to meet the demands of load-carrying capacity, size, and scale. They are optimized to manage tremendous axial loads and demonstrate consistent performance under typical operational conditions.

In other shaft types, an arrangement of Taper and Cylindrical Roller Bearings is used to support load and rotation. This combination of bearings provides enhanced load-carrying capacity. Cylindrical Roller Bearings radially distribute loads more evenly than other bearing types. They are known for their durability and reliability, which is crucial in such applications where limited accessibility for maintenance can be expected and long service life is required. Taper Roller Bearings are designed to handle both radial and axial loads and are suited to large applications with single-direction loads.

Wind Turbine Gearbox Bearings

As mentioned, the gearbox of a wind turbine is instrumental in the turbine's overall ability to generate power. Wind turbine gearboxes are subject to inconsistent loads, vibrations, and changing temperatures, which the gearbox bearings must be able to withstand.

According to the National Renewable Energy Laboratory's Gearbox Reliability Database 2016, bearing failure represents over 75% of wind turbine gearbox failures. With the maintenance costs associated with replacing failed bearings, gearbox bearings can be considered the most critical component in a wind turbine.

A combination of bearing types is implemented depending on the gearbox arrangement in use. Cylindrical and Taper Roller Bearings are used for the planetary gear and carrier, high-speed and high-speed intermediate shaft, and low-speed intermediate shaft.

As discussed previously, Cylindrical Roller Bearings (CRBs) are designed for increased load capacity and speed ratings thanks to their high strength and radial rigidity. Full complement type Cylindrical Roller Bearings contain the maximum number of rollers possible and can support much heavier loads than their cage type counterparts. Single and double row Taper Roller Bearings (TRBs) are utilized in different places within the gearbox.

Single row Taper Roller Bearings are highly rigid radially and axially, capable of handling high radial loads and axial loads in one direction. In contrast, double row Taper Roller Bearings can take axial load in both directions.

Taper Roller Bearings are available in a large range of sizes and are some of the most expensive components of the driveshaft. Ball bearings, including Four Point Contact Bearings and Deep Groove Ball Bearings, are also used on the high-speed shaft and the conduit tube.

Wind Turbine Generator Bearings

The biggest dangers to the Deep Groove Ball Bearings and Cylindrical Roller Bearings primarily used in wind turbine generators are electrical currents. Stray currents transmitted through the bearings heat the material they come into contact with and can cause surface damage, like micro-pitting.

The heat applied can also cause the bearing's lubrication to burn and be consumed faster, drastically reducing the lubricant's service life.

These effects can lead to bearing failure and, potentially, generator failure. Insulated bearings are used to protect against this kind of damage as they do not conduct electricity. A ceramic coating is applied to the bearing's outer rings for small currents or, for higher degrees of protection, to the outer rings and the rolling elements.

The reduction in surface and heat damage preserves the service life of both the bearing and lubrication, minimizing bearing and generator failure and extending the time between maintenance periods.

Bearings prove to be critical components for wind turbines. Trusting the bearings to perform consistently and reliably in some of the most challenging and dynamic environments is crucial for those involved in the maintenance and running of these machines.

Industry-leading bearing manufacturers SKF, NSK, FAG and Timken each design and manufacture bearings specifically for wind turbine applications. These renowned brands offer solutions for each application and bearing type discussed in this article.

Quality Bearings Online has proudly stocked and supplied each of these globally recognized brands for over 10 years to over 110 countries worldwide.

Our award-winning team is on hand and ready with expert technical advice and industry knowledge to help fulfill your bearing needs. Contact us today to discuss your requirements and find the perfect solution for you.

Recent Posts

-

The Future of Bearings: Emerging Technologies and Trends

What interesting developments are shaping the future of bearings? The first ball bearing w …22nd Apr 2024 -

Why Bearings Fail

Monitoring and maintenance are fundamental to maximising bearing service life and machinery perfo …15th Feb 2024 -

Quality Bearings Online receives Feefo Platinum Trusted Service Award 2024

We are pleased to announce that we have won the Feefo Platinum Trusted Service Award for 2024. T …5th Feb 2024