The Benefits of Rubber Seals vs Metal Shielded Bearings

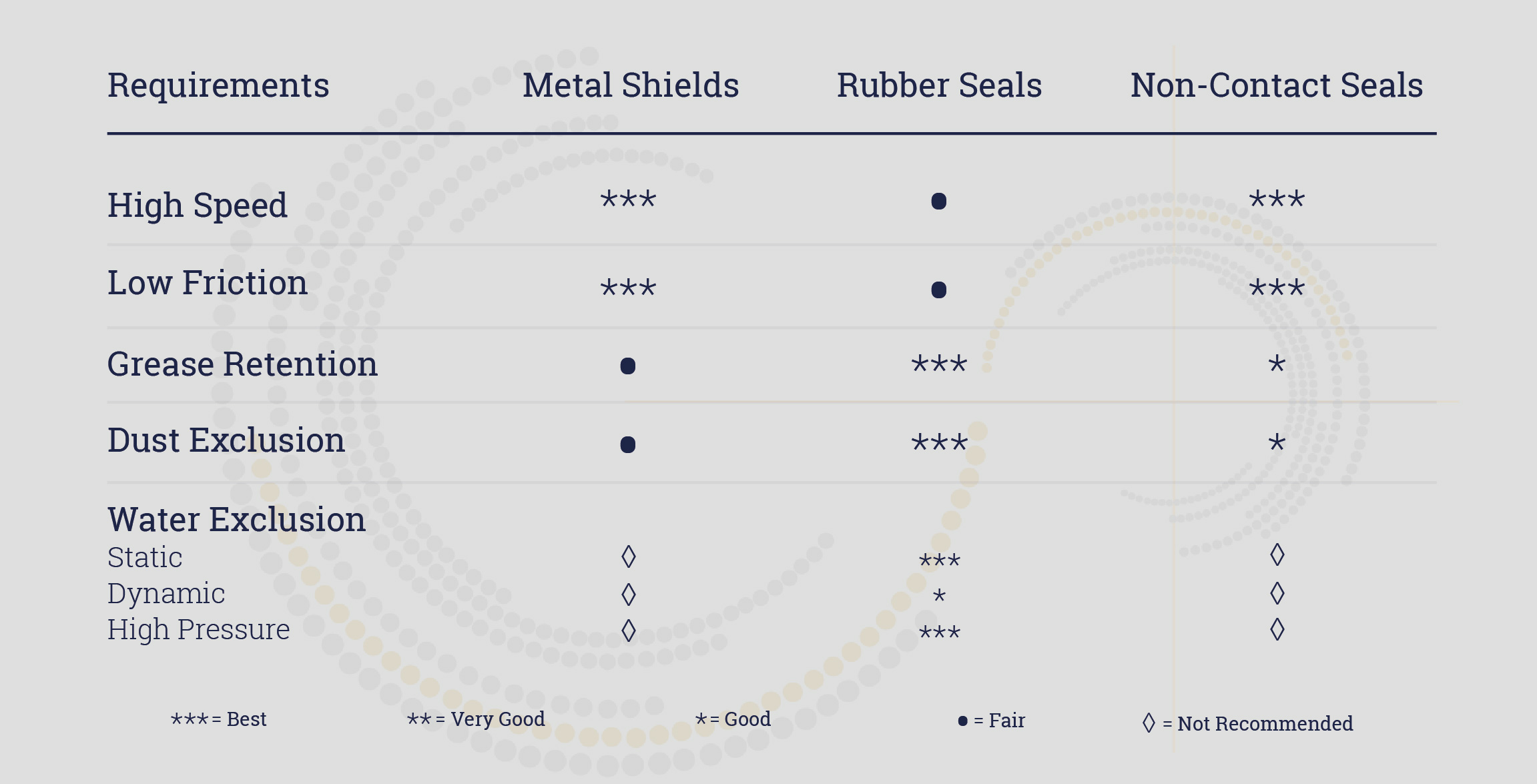

There are many factors to consider when choosing whether a Rubber Sealed or Metal Shielded Bearing is the most suitable for your application. Compared to Open Type Bearings, Sealed and Shielded Bearings provide better protection against contamination and retaining lubrication. However, to maximize the service life of a bearing and the performance of your machinery, the operational conditions need to be considered, as Rubber Seals and Metal Shields have different performance capabilities. Read on a breakdown of shielded vs sealed bearings.

Metal Shielded Bearings

Metal Shielded Bearings are often used in applications with risk of contamination where speed is still a priority, as they have no contact with the inner ring, ensuring low friction levels.

Metal Shielded Bearings are often used instead of Rubber Sealed Bearings due to their speed capabilities. However, compared to Rubber Seals, they are not as good at protecting against moisture and fine dust, so this is something to consider when deciding whether Metal Shielded Bearings are the best option for your application.

Rubber Sealed Bearings

Rubber Sealed Bearings are considered maintenance-free as they are ‘sealed for life’ and do not require re-lubrication. Rubber Seals prevent loss of lubrication, and the bearings are pre-packed with the correct amount of lubricant.

Rubber Sealed Bearings prevent moisture from entering the Bearings to avoid rust and ensure the lubrication does not wash away. When choosing a bearing, speed is an important factor to consider. Speed can be impacted in bearings with Rubber Seals due to the friction created where they have contact with the inner and the outer race.

Non-contact Sealed Bearings

Bearings with Non-Contact Seals are similar to Metal Shielded Bearings as they can operate at the same speeds. However, these Bearings benefit from an improved sealing efficiency compared to Metal Shields.

Both Sealed and Shielded Bearings are available with one or two Rubber Seals or Metal Shields. This accommodates applications where a housed Bearing needs access to lubrication from one side while preventing moisture and contamination from entering at the other side.

Here at Quality Bearings Online, we have a wide range of Rubber Sealed Bearings and Metal Shielded Bearings across world renowned brands such as SKF, FAG, NSK, and Timken.

If you are unsure on whether you need a Rubber Sealed Bearing or Metal Shield Bearing for your application, speak to a member of our knowledgeable sales team who will be able to offer advice on the best solution. Contact us today.

Are you looking for Shielded Bearings or Sealed Bearings? Shop with Quality Bearings Online today.

Frequently Asked Questions

Metal shield bearings v sealed bearings - which is better?

Deciding whether to use a metal shielded bearing or rubber sealed bearing is greatly dependent on the application, environment, and operating conditions. Metal shielded bearings are a low friction option as they are fitted in the outer ring and have no contact with the inner ring. The lack of contact allows the bearing freer movement and facilitates higher operating speeds, however it also allows for the possibility of contaminants entering the bearing. There are a few options for rubber seals, but standard rubber seal bearings have contact with both the inner and outer ring of the bearing which generates more friction than metal shields. As such, bearings with rubber seals won’t operate at the same high speeds metal shielded bearings will. Rubber sealed bearings, however, are the best for keeping out contaminants, including water. Metal shielded bearings are not recommended to be used in applications where contact with water is possible.

What are the advantages of using rubber sealed bearings?

Sealed bearings prevent contaminants like dust from entering the bearing, reducing wear and extending the bearing's lifespan. Sealed bearings often require less maintenance, as the protective seals help retain the bearing’s grease and don’t require relubrication - they are often referred to as ‘sealed for life’. These advantages make sealed bearings suitable for applications where regular maintenance may be challenging or impractical.

Do Shielded Bearings have more friction?

No, shielded bearings do not produce more friction than sealed bearings as the shield only has contact with the outer ring of the bearing allowing for freer movement of the inner ring. This design allows the inner ring to move more freely, resulting in lower rotational resistance. In contrast, sealed bearings usually have rubber or synthetic seals that make light contact with both the inner and outer rings, which can increase friction slightly, though they provide better protection against contaminants.

Cost and maintenance of rubber sealed bearings vs metal shielded bearings.

Rubber sealed bearings are typically slightly more expensive than shielded bearings. Their rubber seals are more complex than metal shields and are fitted in a different way. Bearings with metal shielded bearings may be cheaper initially, but choosing between these types should not come down to expense alone. Depending on the application, rubber seals may be more appropriate, for example if there are a lot of contaminants present or contact with water is more likely. In this case, a metal shielded bearing would eventually fail and replacing it would require additional cost. However, if your application requires the bearing to run with low friction at high speeds, a rubber sealed bearing would also fail as it would be operating in conditions it is not designed to withstand.

When choosing shielded bearings v sealed bearings, consider your application’s operating conditions. It’s also important to consider the amount and ease of performing maintenance on your bearings and machinery to help you choose the correct bearing.

Contact Us

Recent Posts

-

Gold Accredited by Investors in People

Quality Bearings Online Ltd has been awarded the prestigious Investors in People Gold accreditation, …21st Jan 2026 -

Top 8 Reasons Why Spindle Bearings Fail in CNC Machines

Spindle bearing failure in CNC machines can be extremely frustrating, as it can result in unexpected …1st Dec 2025 -

A Step-By-Step Guide To Fitting Bearings Properly

Bearings are the critical parts of countless mechanical applications, from the wheels on cars to the …14th Nov 2025