5 Reasons Why Transmission Belts Fail

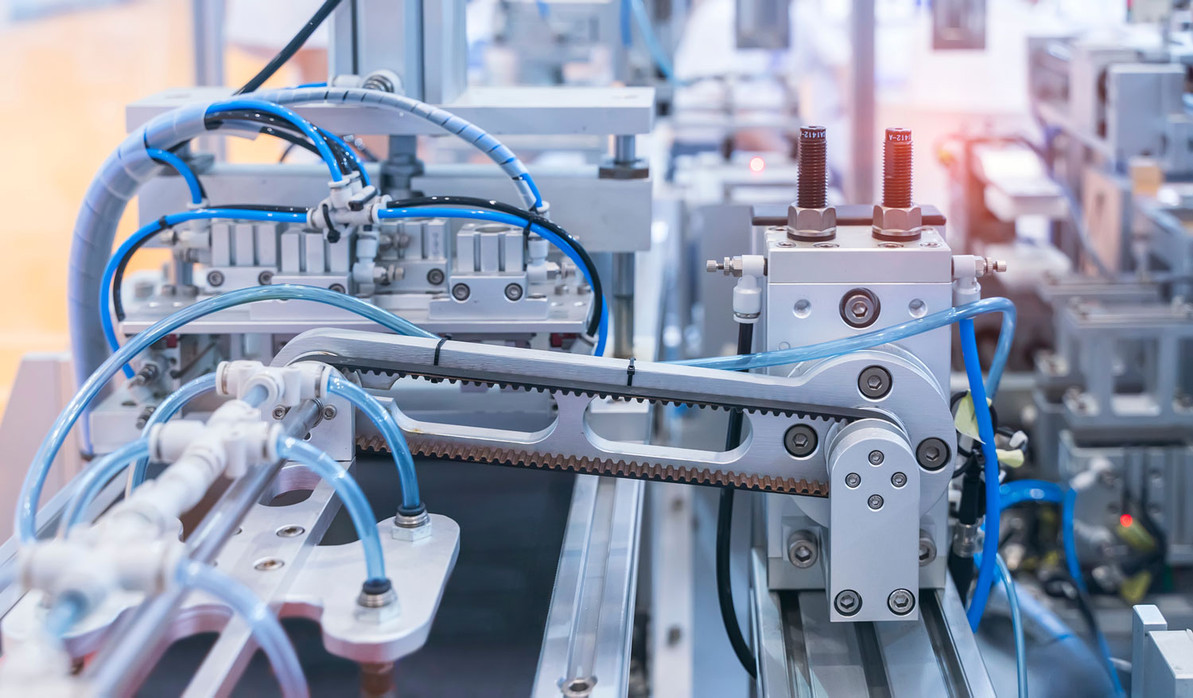

Taking care of your transmission belts will help you to avoid any under performance activity as well as keep the belts for a longer period of time. There are many different reasons why a transmission belt may stop working. Today we’ll tell you the top 5 reasons why a belt might fail:

- Misalignment

Misalignment is one of the main causes of belt failure. It occurs when there is an excess or a lack of tooth wear, and it causes edge damage. This problem can be solved by checking the belts regularly and aligning its shafts and pulleys.

- Excessive load

An excessive amount of load can negatively influence the tension of the belt. Consequently, an excess of tension in the belt can produce a land wear. To improve this problem, it is necessary to redesign the drive.

- Low Quality Unbranded Belts

Buying a low-quality non-branded product may influence your production in the long term. A big disadvantage of using low-quality belts is that it is more likely to fail. Getting a high-quality belt assures a long-life and a better performance.

- Under-tensioned Belt

If you don’t use a tension gauge to measure the tension of your belts, your belts may be under-tensioned. An extremely low tension or loss of tension during the running can negatively affect the teeth of the belt by leaving hollowed teeth or tooth shear. Also, the levels of belt noise may increase when there is a lack of tension.

- Lack of Maintenance

If you take care of your transmission belts, all the above can be solved in time. Regular maintenance helps to avoid oil contamination, belt noise, cracks on the back of the belt or high/low temperature. Constant maintenance not only avoid problems, but also allows you to spot problems before they can damage the belt permantly.

Transmission Belts are commonly used to link two or more rotating shafts mechanically. At Quality Bearings Online, we understand the importance of these materials in the everyday production, so we offer the best and highest quality brands in the market, ContiTech Sync Belts.

ContiTech is a world leading power Transmission Company that covers the needs of different sectors such as automotive, industrial and agricultural. On our website you can find a wide range of ContiTech Products categorized as blue, green, orange, purple, red, white or yellow belts.

Recent Posts

-

Why Bearings Fail

Monitoring and maintenance are fundamental to maximising bearing service life and machinery perfo …15th Feb 2024 -

Quality Bearings Online receives Feefo Platinum Trusted Service Award 2024

We are pleased to announce that we have won the Feefo Platinum Trusted Service Award for 2024. T …5th Feb 2024 -

How Do Bearings Support Clean Wind Energy?

Wind turbines are revolutionizing the energy industry, shifting consumers away from fossil fuels, …18th Jan 2024